Centroid "Allin1DC" DC servo motor based closed loop CNC Controller

This is a legacy page, to view up-to-date information and pricing please visit the Allin1DC Page on ShopCentroidCNC.com

DIY Allin1DC CNC Controller Kit #14999

DIY Allin1DC CNC Controller Kit

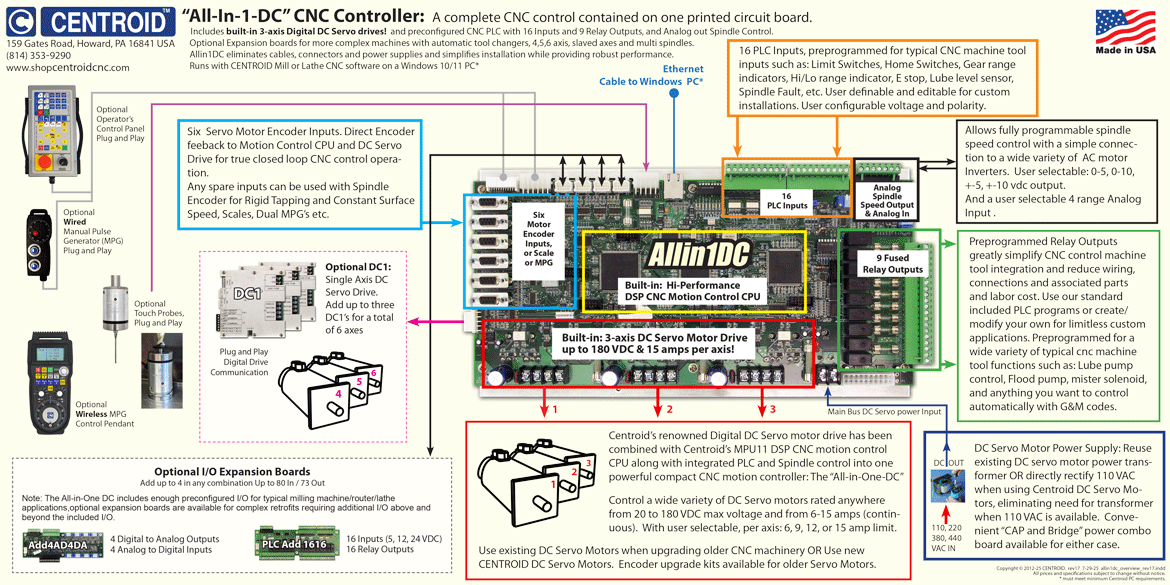

Add to CartCentroid Allin1DC CNC controller kit (part # 14999) includes:

- Allin1DC CNC control board; a True Closed Loop CNC controller

- Logic power supply with power leads

- DIY Cable connector kit

- 15’ Shielded Ethernet cable

- 3-Axis Digital Servo Drive,

drives up to 40in-lb/4.52Nm DC servos up to 180VDC

- Typical CNC machine tool pre-programmed PLC Inputs and Outputs

- Mill and Lathe Conversational Programming Software

- Installation and Operator’s manuals PDF

- Full Size Paper Wiring Schematic

- DIY self service CNC support through Centroid Community CNC Forum which is Centroid Technician monitored and maintained.

- Optional Centroid Factory Engineer remote or phone technical support

- Centroid CNC12 "FREE" version of CNC software. (Purchase Pro or Ultimate for additional feature set, see below.)

CNC12 Software Licenses

CNC12 Mill CNC Software License

See Pro and Ultimate License feature set in comparison table below

If you purchase License at the same time as the Allin1DC, the License will be sent via E-mail delivery. M-F 8-5 EST USA

Note: Each Software License is specific to a single CNC control (Oak/Allin1DC/MPU etc) not the CNCPC

If you are purchasing a license for a previously ordered Allin1DC kit please email a fresh report.zip file to diysales@centroidcnc.com along with your paypal receipt to expedite delivery.

CNC12 Lathe CNC Software License

See Pro and Ultimate License feature set in comparison table below

If you purchase License at the same time as the Allin1DC, the License will be sent via E-mail delivery. M-F 8-5 EST USA

Note: Each Software License is specific to a single CNC control (Oak/Allin1DC/MPU etc) not the CNCPC

If you are purchasing a license for a previously ordered Allin1DC kit please email a fresh report.zip file to diysales@centroidcnc.com along with your paypal receipt to expedite delivery.

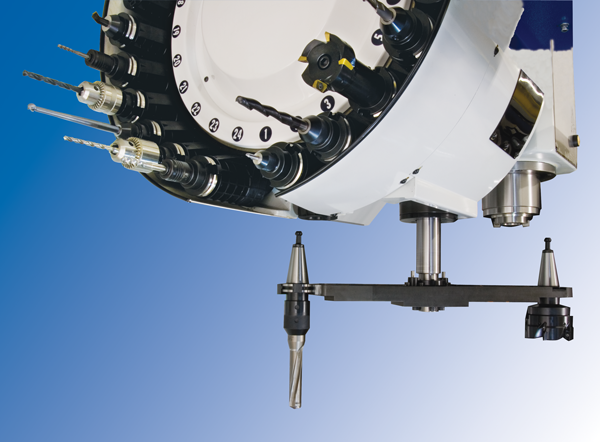

ATC capability plug in for Allin1DC

Add to CartThis plug in is required for an Allin1DC system that will be running a Tool Changer. A Pro or Ultimate License is required for full ATC capabilities

Customized Allin1DC CNC controller kits

Can't decide what you need?

We will put together a Custom CNC control DIY kit for your particular CNC machine tool:

We've been upgrading machine tools since 1979 and have machine tool knowledge that can save you time and money. We can package the CNC control board, axis motors, encoders, cables, power supplies, and schematics; everything you need, into a custom DIY Allin1DC CNC control kit specific for a specific machine tool.

Fill out this CNC control quote request form and we will advise, build and price the cnc system for you..

If reusing servo motors send us photos of the motors and the motor data plates so we can advise on compatibility with Allin1DC. send to:. diysales@centroidcnc.com

Allin1DC CNC controller upgrade kit for Bridgeport, Anilam, Dynapath and others when reusing existing servo motors and upgrading to new encoders #15026

Allin1DC CNC control kit for Bridgeport Boss 8-12 / V2XT / V2ES / EZ Trak, Heidenhain TNC 145 Interact I or II , knee mills and many other machine tools with Anilam, Dynapath and other old CNC controls that used DC servo axis motors.

This kit is intended for reuse of existing servomotors replacing the stock low-resolution encoders with new 2000 line (8000 ppr) units which dramatically increases the performance, and accuracy of the machine tool. See this PDF for more info.

Kit includes:

– ALLIN1DC CNC controller kit

– Qty. 3 2000 Line (8000 ppr) Encoders (specify motor encoder shaft diameter)

– Qty. 3 Pre-Wired 16' Servo Power and Encoder Cables.

(plug and play with new encoders)

– Capacitor and Bridge combo DC power supply with mounting brackets

– Pre configured PLC programs for common machine tools

– Made in USA

This kit works on a variety of CNC knee mills, bed mills, and routers with old Bridgeport, Dynapath, Anilam, Bandit, GE, Allen Bradley and many other CNC controllers. It replaces the old CNC control electronics while retaining the stock DC servos, and other basic controller parts can be reused like contactors, disconnects, fuses etc..See this PDF for more info.

Allin1DC Bridgeport Boss 1-7 CNC upgrade kit with new DC servo motors. #15025

(also works for any machine tool that requires three new 29 in-lb DC servo axis motors)

Designed for Boss 1-7 equipped mills, and any Knee mill or Bed mill that needs new DC servos on all three axes. This retrofit kit includes 3 brand new Made in USA servomotors with 2000 line (8000 ppr) encoders factory installed. The end result is smooth, continuous 3-axis motion. And up to 8x the accuracy of the old controller. You’ll be able to perform CNC operations that simply weren't’t possible with the old control! See this PDF for more info.

Kit includes:

– ALLIN1DC (Motion Control, PLC, DC Drives) True Closed Loop CNC Control

– Qty. 3, 29 in-lb DC servo motors NEMA 42 with plug-and-play 16' cables

– Centroid DC power supply "Capacitor + Bridge Combo" ( use of a transformer is no longer required for DC servo power creation)

– Boss PLC program

– Made in USA

(Note: Bridgeport Boss 1-7 machines were originally equipped with stepper motors. If you wish to retain the stepper motors see our Acorn CNC control board.)

Kit #14504 also works perfectly on a variety of CNC knee, bed mills, routers and other specialty machines originally equipped with stepper motors or missing/damaged servo motors. This kit replaces the old CNC control electronics and axis motors with new closed loop Made-in-USA Centroid DC servo motors while reusing basic controller parts can be reused like contactors, disconnects, fuses etc.. See this PDF for more info.

Allin1DC CNC Controller Lathe Kit with new DC servo axis motors

Kit includes:

– ALLIN1DC (Motion Control, PLC, DC Drives) True Closed Loop CNC Control

– DC servo motors in popular combinations. (16 in-lb on X & 29 in-lb on Z, 16 in-lb on X & 40 in-lb on Z, 29 in-lb on X & 40 in-lb on Z) with 16' cables installed.

– Centroid DC power supply "Capacitor + Bridge Combo" ( use of a transformer is no longer required for DC servo power creation)

– Made in USA

Front or back mount tooling, gang tooling, CSS, Threading, CNC Turret Compatible, Spindle Encoder input, Dual MPG handwheel inputs.

Allin1DC CNC controller upgrade kit for reusing existing servo motors and upgrading to new encoders #15027

Reuse existing DC servo motors by upgrading the encoder and installing this Lathe Allin1DC CNC controller kit. #15027

Kit includes:

– ALLIN1DC (Motion Control, PLC, DC Drives) True Closed Loop CNC Control

– Two servo motor encoders with pig tail connectors

– Two 16' Servo motor Power and Encoder cables

(plug and play with Allin1DC and Encoders)

– Centroid DC power supply "Capacitor + Bridge Combo" (reuse existing step down transformer)

– Made in USA

Front or back mount tooling, gang tooling, CSS, Threading, CNC Turret Compatible, Spindle Encoder input, Dual MPG handwheel inputs.

Made-in-USA Centroid DC Servo Motors. Smooth, Powerful, Reliable, Cable and Encoder pre installed, tested ready to run

- Made in USA

- Windings specifically designed for torque characteristics needed for machine tool use

- Advanced ferrite long life brushes

- 180 VDC max voltage allows direct rectification of 110 vac so no transformer is needed

- 29 and 40 in-lb sizes are Nema 42 for compatibility as replacement motors on a variety of machine tools

- Centroid installed encoder and cable

- Centroid Tested and ready to run

- Backward compatible with older Centroid CNC control systems

- Available sizes: 10 in-lb, 16 in-lb 29 in-lb, 40 in-lb and 40 in-lb with brake

- Used on a wide variety of machine tools from knee mills, bed mills, lathes, VMC's,

Routers and other specialty CNC machinery

Allin1DC accessories, add on just what you need

All-in-one Touch Screen CNCPC

- Preloaded with 11 and pre-configured for CNC PC duty

- Preloaded Centroid CNC software (Free Version) with G code Editor, Intercon, Stock PLC programs, Touch Screen Operators Control Panel (VCP)

- Touch Screen

- Wifi, Ethernet, webcam with mic, card reader, usb ports

- Powercord, Keyboard, Mouse

- Centroid tested and pre qualified to work with Centroid CNC controllers

- Model, Specifications and COLOR may vary.

Note: There are NO VESA mounting holes on this unit.

Planning to build or use your own PC as a CNCPC? Be sure the PC meets the Centroid CNCPC minimum requirements found here. The Centroid's latest CNC software requires a Windows 10 or 11 PC that meets the requirements.

- If you plan to build your own CNCPC follow the recommendations here.

- If you plan to buy your own PC we recommend the Intel NUC (be sure to purchase a NUC that meets the Centroid minimum pc requirements) and a 1920x1080 16:9 aspect Touch Screen monitor

- Centroid also offers for purchase CNCPC's with preloaded and pre configured software see below.

Centroid NUC CNCPC for use with your Touch Screen LCD display

Centroid Intel NUC CNCPC

- Allows use of any size and type LCD Touch screen or regular LCD monitor.

- Higher Performance PC than the the above Allin1PC

- Intel SSD for the best performance

- Preloaded with a licensed copy of Windows 11 and Windows is pre-configured for CNC PC duty

- Preloaded Centroid CNC12 software Mill and Lathe, Free version

- G code Editor

- Intercon Conversational

- Stock PLC programs

- Touch Screen Operator Control panel.

- SSD (solid state drive)

- Display port, HDMI, Ethernet, USB

- Centroid tested and pre qualified to work with Centroid CNC controllers

CENTROID Wireless MPG CNC control pendant

WMPG-6 (PDF download)

Add to CartInternational shipping is calculated during checkout.

Requires CNC12 v4.16+ and a Pro License

Take the control to where the work is! A game changing tool, the Centroid Wireless MPG handwheel CNC Control pendant allows the operator to conveniently and precisely set up jobs and tools remotely.

Plug and Play with Centroid CNC12 Pro Acorn CNC software and CNC12 for Oak, Red Oak and Allin1DC with the USB MPG software plug-in.

SImple and fast setup. Plug in the included USB transmitter/receiver and start using it! Perfect for all types of Mills, Lathes, Routers and other specialty CNC machines. click here for more info.

KP-3 CNC touch probe

Part, Vise and Fixture Probing: Automatically Set Zero points fast and accurate.

Use the KP-3 probe to quickly and accurately find zero points on a vise, fixture or part. Eliminate operator error when setting zero points, finding edges, or center locations of bosses or bores, slots and webs. Eliminates the need for a centerfinder or an edgefinder. You'll never have to spend 30 minutes using a center finder to locate the center of a bore again. The probe will find and set the center of a bore in just seconds. In addition the probe can be used to verify part dimensions and locations and many other applications. The KP-3 mounts in any 1/2" tool holder and has concentric adjustment screws. Patented and Made in USA. click here for more info and video on the KP-3

KP-3 Allin1DC kit part # 14944

- KP-3 probe

- 2.5 mm x 40mm carbide stem, ruby tipped stylus

- Stylus wrench

- KP-3 to bulkhead cable

- Bulkhead cable to Allin1DC

-

- KP-3 Users Manual

CENTROID TT-4 CNC Tool Touch Off: Automatic Tool Height Measurement, Automatically sets Tool height offsets

Quickly and accurately setup tool heights in the tool library with a push of a button. The CENTROID TT-4 automatic tool height offset touch probe is plug and play with all Centroid CNC controls. Eliminates gauge blocks, paper, and repeated measurements. Save time and increase accuracy. Fully integrated into the CNC control tool library menu, just select the tool and press auto measure to set the tool height automatically. Makes measuring all types of tools faster and more accurate. Find the longest insert in a multiple insert tool quickly. Once you start using the TT-4 you'll wonder why you waited to purchase this time saving tool. Measure just one tool or a whole group of tools at once. Can also be used in the middle of a job to measure a replacement tool. Integrated with an Automatic tool changer for batch tool measurement. The TT-4 is based on KP-3 touch probe technology and is a robust kinematic design and works with all spindles even ones that with non conductive bearings (ceramic) or tooling that doesn't conduct (diamond).. Acorn CNC software configuration is simple one button press with the pre configured preset for the TT-4 using the Acorn Setup Wizard. Note: Also compatible with most all other CNC controller such as but not limited to: Mach3/4, WinCNC, LinuxCNC, Pathpilot and others.

Centroid CNC Operator's Console, Mill or Lathe versions with or without CNCPC

- 15" Touch Screen full color LCD display

- Dedicated Operator Control Panel with extra programmable buttons

- USB ports

- Thin at 2.88" Thick

- Made in USA Steel construction

- Uses Standard USB keyboards, keyboard included

- Variety of mounting possibilities

- Compatible with Allin1DC, OAK and MPU11 systems. (not compatible with Acorn)

- Optional Custom Control Panel Overlays are made to order for specialty machine tools. call or email for details.

- Preloaded Centroid CNC software (Free Version) with G code Editor, Intercon, Stock PLC programs, Touch Screen Operators Control Panel (VCP).

Available with built-in CNCPC or without CNCPC.

Available in "panel mount" configuration for mounting in existing console enclosure. (Panel Mount = made to bolt into an existing machine tool console space. Typically used on large machines with a preexisting CNC control so existing console hardware can be re purposed with new Centroid CNC operators console. )

Build your own console to machine mounting hardware or use any of Centroid various Arm and Console Floor Stand mounting options, click here for dimensional drawings

Download Centroid CNC console brochure click here..

Optional pre assembled "Console to Electrical cabinet cable in conduit" Standard size: 16' cables with 6' conduit. (part# 11028). Custom lengths avalible.

Centroid Operator's Control Pendant, Mill, Lathe or Router versions.

Same control panel that is on the M400/T400 CNC consoles but placed in a box with a cord.

Centroid CNC software allows operator machine control through a number of different methods.

This Operator's Control Pendant is for when hard buttons are preferred over touch screen controls. Useful on large and small machine tools alike when setting up parts, fixtures and tools, the pendant allows the operator to take the controls to where the work is. Steel case with magnets on the back and rubber handles, this control pendant uses the same operator control panel found in the M400/T400 CNC console.

The control panel can be removed from the pendant and flush mounted in your own console enclosure as well.

A lower cost ($0) alternative to this piece of hardware is the software based Touch Screen Virtual Machine Control Panel (VCP). The VCP allows the functionality of this Hardware based Operators Control Pendant when using a Touch Screen LCD as the CNC control display. The touch screen VCP is included with Centroid CNC control software CNC12 v4.12+ and can be used without or in conjunction with this hardware based Operator's Control Pendant.

Longer cords up to 50' are available call for quote or just use the Wireless MPG for long distance applications.

Servo Motor Upgrade Encoder Kit

Commonly used to upgrade old existing DC servo motors to be compatible with the Centroid Allin1DC. see this web page with photo pictorial showing a typical servo motor encoder upgrade. Replaces Tachometers, Resolvers and Low resolution Encoders. Upgrade existing DC servos to the latest technology for silky smooth closed loop CNC operation. Centroid stocks these high resolution, 5vdc, quadrature differential encoders in several commonly found shaft sizes. Encoder to Encoder cable pigtail included which allows plug and play compatibility with Centroid Encoder Cables, No crimping or soldering needed. Please measure the servo motor encoder shaft diameter before ordering. More technical how to information on Encoders here..

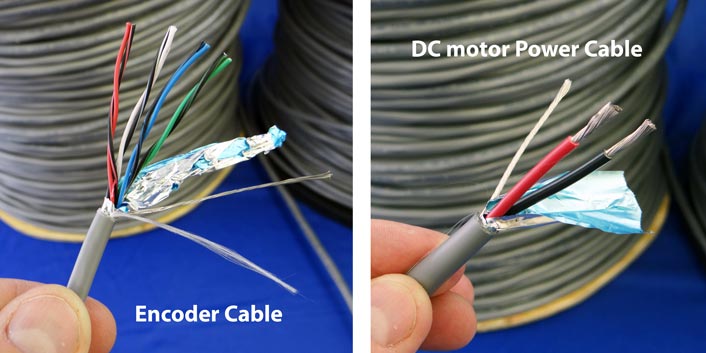

Plug and Play Centroid DC Servo Motor Power and Encoder Cable

Typically used for replacement or retrofit upgrade of an existing DC servo motor for use with the Allin1DC CNC controller. You can make your own cables or buy these ready to go units to save time. High quality Cable with Polyurethane jacket, Color coded encoder cable is twisted pair with Shield and Drain for proper noise immunity. Power cable is high quality stranded copper with proper terminals at both ends for plug and play use with the Allin1DC. Both cables have thick rubber liquid tight strain relief seal at the motor end.

Custom Lengths over 20' available on a made to order basis.

Centroid Servo Motor Cable "Direct Wire" Seal and Strain Relief Cap (#5031)

For use with Centroid motor cables, this direct wire cable strain relief makes a water/oil tight seal against both the motor power and encoder cables to any flat surface. Very useful when converting both old and new servo motors to a direct wire configuration as seen on this page.

Centroid part# 5031 (aluminum cap, gasket, 6-32 screws)

Centroid DC1 single Axis DC servo drive

Centroid DC1 single Axis DC servo drive. (#11112)

Add to Cart

Add a 4th Axis the Allin1DC with the DC1 single axis digital servo drive

The DC1 axis add-on servo drive is designed with simplicity in mind. The drive is a plug-n-play addition to the Allin1DC CNC control board. This drive can be used for rotary or linear axes.

-

Includes 4th axis software and programming capabilities.

- Digital Communication between Allin1DC and the DC1.

- Additional DC1's simply Daisy Chain with one another back to the Allin1DC

- The communication cable is included (not shown)

- Connect up to three DC1's to an Allin1DC CNC control board

- Allows the Allin1DC to become a 4 axis, 5 axis or 6 axis CNC control

PLCAdd1616 I/O expansion board. Add on additional Inputs and Outputs to the Allin1DC (#11025)

- Add an additional 16 optically isolated inputs and 16 relay outputs to the Allin1DC

- Plug and Play, PLCAdd1616 to Allin1DC communication cable included.

- Typically used to control an Automatic Tool Changer

- User definable inputs and outputs

- User configurable, commanded by the Allin1DC PLC program

- PLCAdd1616 user manual

Add4AD4DA expansion board. Add an additional analog to digital inputs and digital to analog outputs to the Allin1DC (11141)

- Add additional 4 analog to digital inputs and 4 analog to digital

- Plug and Play, Add4AD4DA to Allin1DC communication cable included

- Typically used for multiple spindle machines tools with individual VFD's for each

- User configurable, commanded by the Allin1DC PLC program

- Add4AD4DA user manual

| Features | CNC12 Free v5.0+ | CNC12 Pro v5.0+ | CNC12 Ultimate v5.0+ |

|---|---|---|---|

| Mill and Lathe Intercon Conversational programming | Limited to 20 blocks of conversational | Unlimited | Unlimited |

| Wireless MPG Pendant support *** | Not included | Included | Included |

| G-code program size | Limited to 50Kb Mill , 5Kb Lathe G-code file size | Unlimited G-code file size | Unlimited G-code file size |

| Work Coordinates Systems (WCS) | One (G54) | Eighteen (G54-G59 plus extended WCS) | Eighteen (G54-G59 plus extended WCS) |

| Menu driven Probing cycles | Center of bore | Complete Set of menu driven probing cycles. Bore, Boss, Slot, Web, Inside Corner, Outside corner, Single edge find, find angle, auto probe for CSR | Complete Set of menu driven probing cycles. Bore, Boss, Slot, Web, Inside Corner, Outside corner, Single edge find, find angle, auto probe for CSR |

| Menu driven Digitizing cycles | Grid, Radial, Contour, Wall following, limited to 2500 points | Grid, Radial, Contour, Wall following, limited to 2500 points | Unlimited point Grid, Radial, Contour, Wall following |

| Auto Tool Height Measurement | Unlimited auto measure on: Reference Too l & Tools 1,2,3 |

Unlimited auto measure on all tools. |

Unlimited auto measure on all tools. |

| Coordinate System Rotation | Yes | Yes | Yes |

| Auto find CSR with Probe | No | Yes | Yes |

| Manual find CSR with Probe or Wiggler | Yes | Yes | Yes |

| Manual enter angle for CSR | Yes | Yes | Yes |

| Tool Library | 10 Tools | 200 Tools, (99 Tools Lathe) | 200 Tools Mill, (99 Tools Lathe) |

| Sub Programs and Macros (M98 & G65) Write your own custom macros, many uses |

Not Included | Included | Included |

| Cutter Compensation | Included | Included | Included |

| Backlash Compensation | Included | Included | Included |

| Screw compensation (laser or manual!) | Included | Included | Included |

| 3 axis simultaneous | Included | Included | Included |

| 4 axis simultaneous | Not included | Included | Included |

| 4 th Axis linear or rotary conversational programming. | limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Operate as a 2 axis CNC with Manual Quill | Included | Included | Included |

| Operate as a 2 or 1 axis CNC control | Included | Included | Included |

| Any axis can be Linear or Rotary | Included | Included | Included |

| Spindle Encoder feedback, w/ RPM display | Included | Included | Included |

| Mill Rigid Tapping | Not Included | Included | Included |

| Lathe Threading | Not included | Included | Included |

| Lathe Automatic CSS | Not Included | Included | Included |

| Lathe Rigid Tapping | Not included | Included | Included |

| Lathe C axis | Not Included | Not included | Included |

| Lathe Automatic Tool Measurement | Unlimited auto measure on: Tools 1,2,3 |

Unlimited auto measure on all tools. | Unlimited auto measure on all tools. |

| G81 drilling cycles | Included | Included | Included |

| Compression Tapping Gcode Cycles | Included | Included | Included |

| Mill G-code scaling and mirroring | Included | Included | Included |

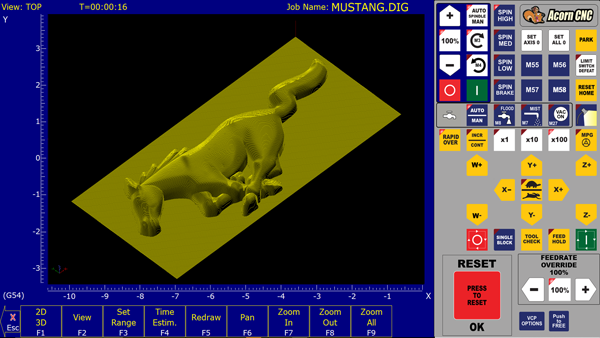

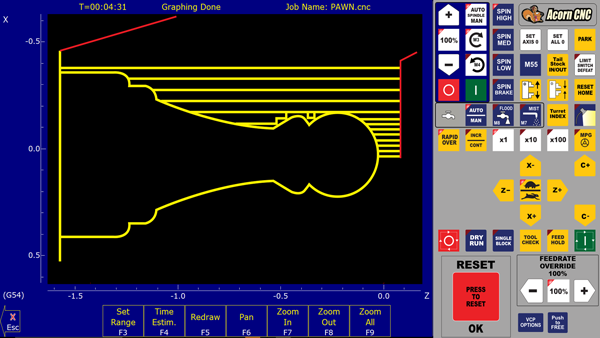

| True G-code backplot graphics | Included | Included | Included |

| Run Time Program Graphics | Included | Included | Included |

| Smart Search (stop and restart at any point) | Included | Included | Included |

| User Configurable Touch Screen Virtual Control Panel ** | Included | Included | Included |

| Backlash compensation | Included | Included | Included |

| Menu driven Part and Tool setup menus | Included | Included | Included |

| Intercon Teach Mode | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Drilling cycles: Drilling, Deep Hole, Chip Breaking | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Pocketing: Circular, Rectangular, Irregular | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Contouring | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Threadmilling | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Conversational Compression Tapping | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Auto Connect Radius | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Lathe Cycles. Auto profile cleanout, grooving, cutoff, chamfer, turning, end face turning, | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Math / Geometry Help | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Operate in Millimeter or Inches | Yes | Yes | Yes |

| 4th axis Jogging | Yes | Yes | Yes |

| Software Axis pairing. Pair an axes with the 4th or 5th axis. Allows Two axis to be paired axes. | No | Yes | Yes |

| Auto Squaring of Software Paired axis with auto homing | No | Yes | Yes |

| Hardware Axis Pairing | Yes | Yes | Yes |

| 4th axis G-code moves: 4&1, 4&2, 4&3, 4&1&2, 4&2&3, 4&1&3&4, 4&1&2&3 |

No, "Free" is limited to 3 axis simultaneous . |

Yes, 4 axis simultaneous movement with full interpolation |

Yes, 4 axis simultaneous movement with full interpolation. |

| Scale Input for axis positioning feedback | No | No | Included |

| M0 Jogging | No | Included | Included |

| PLC Detective Software | Included | Included | Included |

| Use one input for all axis Homing | Included | Included | Included |

| ATC support plugin | No | Requires ATC Software Plug-in | Requires ATC Software Plug-in |

| Five axis or more fully interpolated simultaneous G code moves | Requires purchase of Ultimate Plus | Requires purchase of Ultimate Plus | Requires purchase of Ultimate Plus |

*** Wireless MPG support for machines NOT using a stock v4.16+ PLC program require their custom PLC program to be edited and tested which requires PLC programming.

** VCP support for machines NOT using a stock v4.16+ PLC program require their custom PLC program to be edited and tested which requires PLC programming

Offline Intercon Conversational programming software, Mill and Lathe (10730)

Offline version of INTERCON conversational programming, for use with Windows desktop PC*

Add to Cart

- Program parts in the comfort of your office.

- Program while the machine is running a job.

- Easy part program transfer from your PC to the control via LAN or USB.

- True G-code backplot graphics, see exactly what the machine toolpath will be.

- Use on the same PC as your CAD system.

- A USB Keylock allows user to install software on as many computers as you want.

- Offline programming USB keylock is shipped the next business day.

- Works with Windows 7/8/10/11

- Download offline conversational programming software here, offline programming software runs without USB keylock but limited to 20 lines of Intercon. Plug in the USB keylock for unlimited conversational programming operation. Choose "Offline" during the installation process.

Related Allin1DC System Optional CNC Components

Industrial quality Estop Button with 2 contact closures: #14534

Add to Cart

- Industrial quality reliable Emergency Stop Button with two switches.

- Two contact closures for two estop circuits

- Use just one contact closure or use both

- For use with the Acorn, Allin1dc and Oak CNC control boards.

- Thru Hole Panel Mount

Wired MPG #11069

Use the Manual Pulse Generator to jog the machine tool, very useful for part and tool setups. Order with or without internal bulk head cable. If you have a factory built M400/T400 CNC control or if you ordered the CNC console conduit cable kit you do not need to buy the internal bulkhead cable. If you are building a DIY CNC control based on the Allin1DC cnc controller you will need the internal bulkhead cable to connect this MPG to the Allin1DC CNC control board.

- 100 pulses per rev

- Axis Selector for 6 axes

- Increment amount selector (user configurable in CNC10/11/12)

- For use with Allin1dc and Oak CNC control boards.

- High quality construction with gold plated connector pins

- Hook hanger mount and magnets on the back of the unit

- Pre configured for use with Centroid CNC11 or CNC12 control software

- Plug and Play with Oak/Allin1DC cnc controls running CNC11 or CNC12 software

Looking fro an MPG for an older CNC10 system? please email us your system serial number

CNC10 Kits numbers had 5 digits. (Note: if you have a 6 digit Kit number that is a CNC11/CNC12 system)

How to locate serial number.

Centroid's "Cap and Bridge Combo" DC Servo Motor Power Generator. (12726)

DC Servo Motor "Cap and Bridge Combo"

Add to CartDirectly rectify 110/120 VAC to produce 155 DC volts for use with Servo motors with max voltage rating higher than 160 VDC, (no step down transformer for motors rated above 160 VDC max, use a step down transformer for motor rated under 160 VDC).

- Easily powers up to four 29 in-lb DC servo motors

- High quality large capacity for smooth DC voltage output

- Pre assembled ready to use

- Commonly used for both new cnc control installations and retrofit upgrades

- For use with DC servo motors which are rated above 160 VDC max volts (such as Centroid DC servos) when not using a step downtransformer.

- Use a step down transformer in conjunction if lower DC voltage output is needed for use with lower max voltage rated DC servos.

Power Conversion Examples:

- 110 VAC input yields 155 VDC out

- 83 VAC input yields 117 VDC out

Please see this DC Servo motor power discussion for more informationDC Servo Power Supply Bridge Rectifier (10674)

Designed to bolt to at least a 12,000 MFD 250 Volt Capacitor (larger is ok), this printed circuit board rectifying bridge includes the diode bridge, in-rush limiter, bleed down resistor and terminals for AC power in and DC power out. The distance between centers of the capacitor terminal is 1.125in. 600 V, 35 A

AC in one side DC power out the other couldn't be more simple. Made in USA

Used to rectify AC to DC for Servo Motor Power use.

Power Conversion Examples:

- 110 VAC input yields 155 VDC out

- 83 VAC input yields 117 VDC out

- AC volts IN x 1.41 = DC volts out

- Requires a 12,000+ mfd or higher rated capacitor

- Bolts to standard size capacity with 1.125" terminal spacing

- Can also be wired to a capacitor, rather than bolt on

- Use with your own Capacitor

- 600 volts max, with 35 amps rating.

DC Servo Motor Power and Encoder Cable sold by the foot. Make your own cables using the same high quality cable we use

DC Servo Motor Power Cable (#1753) For use with 40 in-lb DC Servos and smaller. This is the same high quality 14AWG shielded made in USA wire used in the Centroid Motor/Encoder cable sets listed above. Cable is made with a tough polyurethane jacket. We offer it here for those that want to build their own cables. Motor Power Cable also sold in custom lengths per foot, call or email us. Made in USA

DC Servo Encoder Cable (#1754) This is the same high quality,made in USA 22AWG shielded, twisted pair with drain wire used in our pre-built ready-to-use DC servo motor cables listed above. Cable is made with a tough polyurethane jacket. Also sold in custom lengths, call or email us. Connectors available separately below. Made in USA

Quencharc (aka "Snubbers") is a critical component noise suppression device that is required on all Contactors, Solenoids and external Relay coils, Note: minimum order = qty. 3. (#1819)

Designed for noise suppression of all contactor, solenoid and relay coils to prevent interruption of CNC control communications. One Quench arc should be installed across each coil used in any CNC system.

Contactor in photo not included, Image shows typical Installation of Quencharc across a contactor coil.

Quencharcs are commonly used on all sorts of accessory coils, such as Flood Pump, Mister Solenoid, Vacuum Solenoids, Dust Collection motor starters, Estop Contactors and any other device controlled by a Contactor, Relay or Solenoid.

Tech Bulletin on how to use Quencharcs (aka Snubbers) for Noise Suppression.

DC Servo Motor Power and Encoder Connector Kit (13017)

Motor and Encoder Cable Mating Connectors (13017)

Add to CartMake your own DC servo motor power and encoder cables using this connector kit. connectors for both ends of the cables. Power cable connects to servo motor connectors, power cable connects to Allin1DC. Encoder cable connects to encoder pigtail connector and encoder cable connects to Allin1DC connector.