CNC Controller Kit Comparison

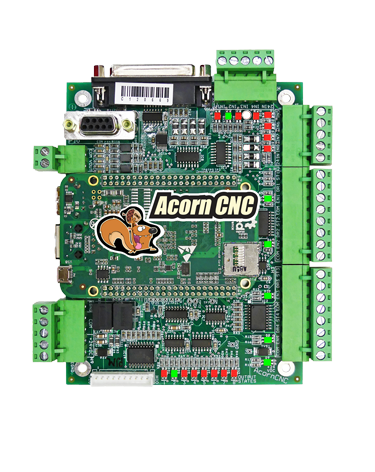

Acorn CNC Controller

- Up to 4 axis Step and Direction, Open Loop or Hybrid Closed Loop

- Hardware Axis Pairing with Auto Squaring

(frees up 4th axis for Rotary)

- Software Axis pairing with Auto Squaring

- 8 inputs and 8 Outputs, Add-on i/o up to 56 in/out

- One Encoder input

(typically used for spindle encoder for Rigid Tapping)

- 1 analog output (0-10/0-5 vdc for Spindle Speed VFD control)

- PWM output (Laser and/or Spindle)

- On board Motion Control CPU

- Ethernet communication to CNCPC

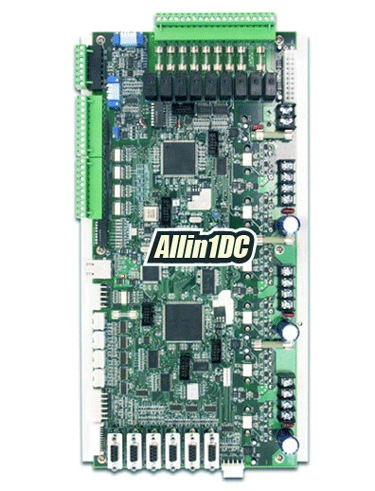

Allin1DC CNC Controller

- Up to six Axis DC servo only, Closed loop

- Up to 272 Inputs and 272 Outputs

- 6 Encoder inputs

- Built-in 3 axis 15 amp per axis DC servo drive

- 1 analog out, 1 analog in, expandable to 16 In / 16 Out

- On board Motion Control CPU

- Ethernet communication to CNCPC

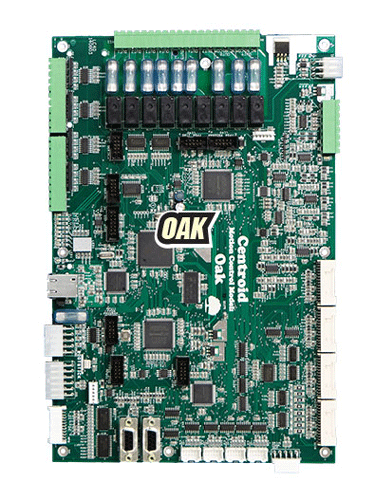

Oak CNC Controller

- Up to 8 axis, AC servo or DC servo, Closed Loop

- Up to 272 Inputs and 272 Outputs

- 6 encoder inputs expanable to 28

- 1 analog out, 1 analog in, expandable to 16 In / 16 Out

- On board Motion Control CPU

- Ethernet communication to CNCPC

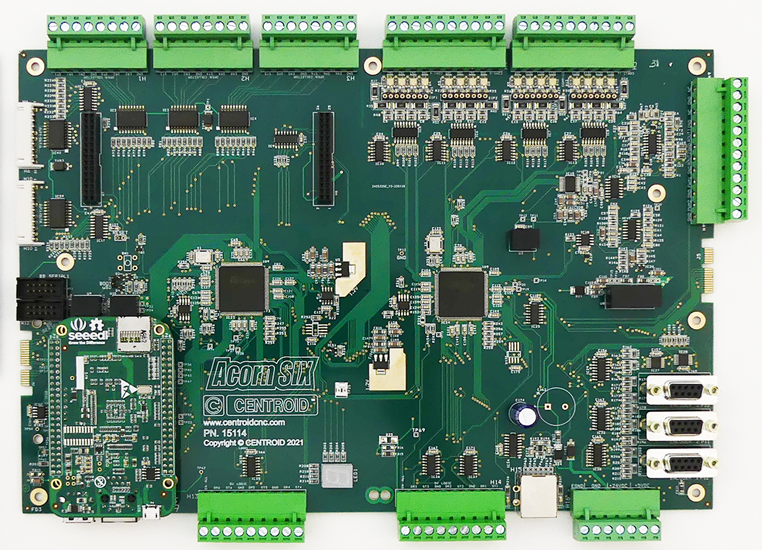

AcornSix CNC Controller

- Up to 6 axis Step and Direction, Open Loop

- 16 inputs and 16 Outputs (Add up to 64 in/64 out)

- Three Encoder inputs

- 2 analog output (0-10/0-5 vdc for VFD control)

- 2 PWM output (Laser and/or Spindle)

- On board Motion Control CPU

- Ethernet communication to CNCPC

- DIY Self Service Tech Support

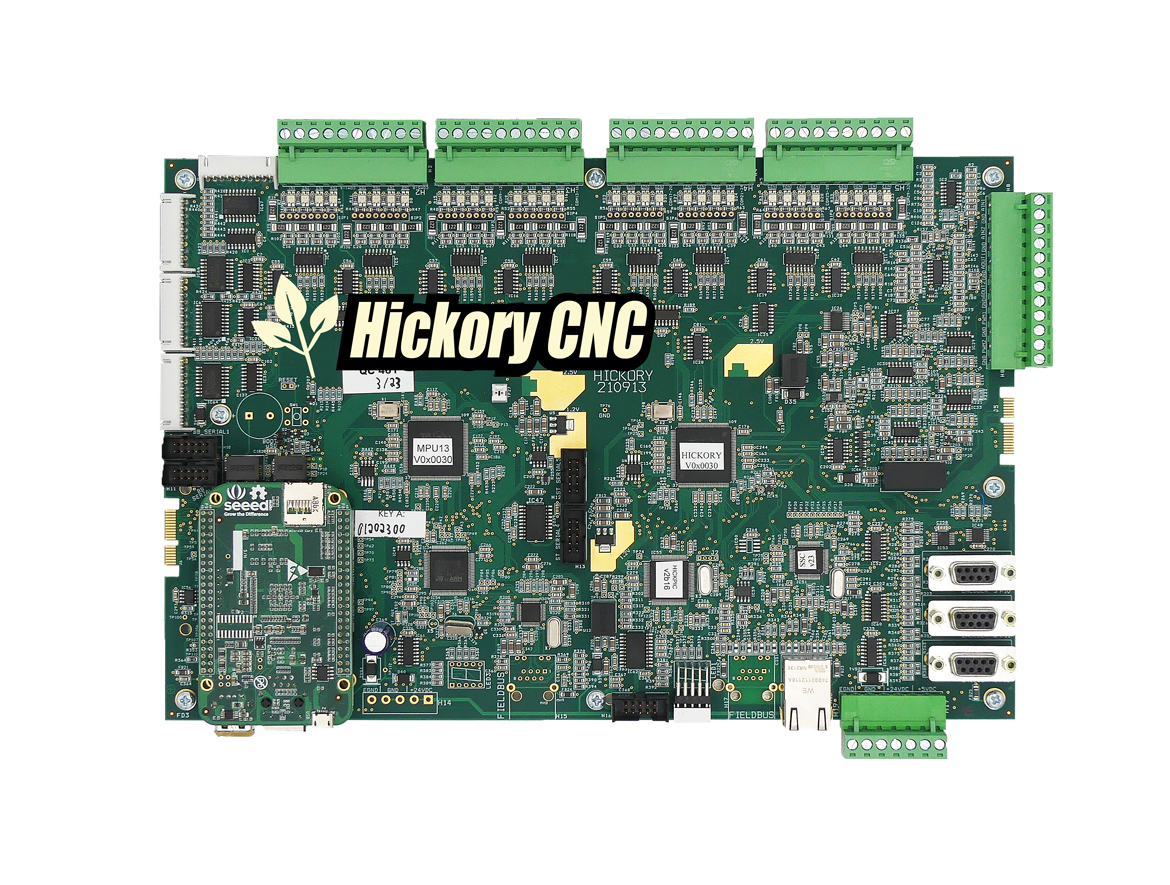

Hickory CNC Controller

- Closed Loop CNC Controller

- EtherCAT Servo Drive Communication Protocol

- Connect up to 8 axes of servo drives, mix and match make/models

- Select from Plug and play Centroid curated EtherCAT servo drive models

- Onboard 32 in, 32 out. (Add up to 80 in/80 out)

- On board Motion Control CPU

- Ethernet communication to CNCPC

- Two Analog Outputs

- Two PWM Outputs

- One Analog Input

- Expandable, add additional i/o, encoder ports, analog in/out

Centroid CNC Control Board Comparison Table

| Acorn | AcornSix | Allin1DC | Oak | Hickory | |

|---|---|---|---|---|---|

| Servo Motor types | Steppers or AC, Open or Hybrid Closed loop. | Steppers or AC, Open or Hybrid Closed loop. | DC Closed Loop w/built-in drives | AC Closed Loop | EtherCat Closed Loop w/ Centroid Curated Drives |

| Maximum number of Axes | 4 | 6 | 6 | 8 | 8 |

| Axis Motor Hardware Pairing | Yes, with auto squaring | Yes, with auto squaring | No | No | No |

| Axis Motor Software Pairing | Yes, with auto squaring | Yes, with auto squaring | Yes, with auto squaring | Yes, with auto squaring | Yes, with auto squaring |

| Compatible with Mills, Lathes, Routers, and other specialty machines | Yes | Yes | Yes | Yes | Yes |

| AC Servo Motor/Drive compatible | Yes, (Step and Direction) | Yes, (Step and Direction) | No | Yes, Position/Precision & Velocity modes | Yaskawa Sigma 7, Glentek Gamma series, Estun Summa, Leadshine EL7 and EL8, Inovance SV660N |

| DC Servo Motor/Drive compatible | Yes, (Step and Direction) | Yes, (Step and Direction) | Yes, up to 15 amps (continuous) per axis | Yes, using the Centroid AC/DC drive up to 60 amps per axis. | No |

| Stepper Motor/Drive compatible | Yes | Yes | No | No | No |

| True Closed Loop Operation | No, Hybrid Closed Loop: Yes | No, Hybrid Closed Loop: Yes. Also supports scales for Position correction | Yes, also supports scales for position correction | Yes, also supports scales for position correction | Yes, also supports scales for position correction |

| Built in Motion Control CPU | Yes | Yes | Yes | Yes | Yes |

| Built in DC servo motor amplifier | No | No | Yes | No | No |

| Built in PLC | Yes 8 In, 8 Out | Yes 16 In, 16 Out | Yes, 16 In, 9 relay out | Yes, 16 In, 9 relay out | Yes 32 In, 32 Out |

| Maximum Inputs and Outputs | 56 in/ 56 out | 96 in / 96 out | 272 In / 272 Out | 272 In / 272 Out | 110 in/ 110 out |

| Optional input output expansion board | Yes | Yes | Yes | Yes | Yes |

| Optically Isolated Inputs | Yes | Yes | Yes | Yes | Yes |

| Fused Relay Outputs | No, installer adds fuse | No, installer adds fuse | Yes | Yes | No, installer adds fuse |

| On board relay output types | Ribbon cable to Relay 8 board (8 relay outputs) | 2x Ribbon cable to Relay 8 board (16 relay outputs) | 7 SPST and 2 SPDT | 7 SPST and 2 SPDT | 4x Ribbon cable to Relay 8 board (32 relay outputs) |

| Built-in Analog spindle control output | Yes 0-10 vdc or 0-5 vdc | Yes, 0-10, +-10, 0-5, +-5 12 bit | Yes, 0-10, +-10, 0-5, +-5 12 bit | Yes, 0-10, +-10, 0-5, +-5 16 bit | Yes, 0-10 15 bit, +-10 16 bit, 0-5 14 bit, +-5 15 bit |

| PWM output for Laser and/or Spindle | Yes, 1 PWM output | Yes, 2 PWM output | No | No | Yes, 2 PWM output |

| Runs on Centroid Mill or Lathe or Router CNC software | Yes | Yes | Yes | Yes | Yes |

| Base Centroid CNC software included with CNC control board price | Centroid CNC12 "Free" CNC software Mill and Lathe, Router, Plasma | Centroid CNC12 "Free" CNC software Mill and Lathe, Router | Centroid CNC12 "Free" CNC software Mill and Lathe | Centroid CNC12 "Free" CNC software Mill and Lathe | Centroid CNC12 "Free" CNC software Mill and Lathe |

| Centroid CNC Software Licenses | Centroid Mill, Lathe, Router Plasma "Pro" CNC software

Centroid Mill, Lathe, Router, Plasma "Ultimate" CNC software |

Centroid Mill, Lathe, Router, "Pro" CNC software

Centroid Mill, Lathe, Router, "Ultimate" CNC software |

Centroid Mill, Lathe, Router, "Pro" CNC software

Centroid Mill, Lathe, Router, "Ultimate" CNC software |

Centroid Mill, Lathe, Router, "Pro" CNC software

Centroid Mill, Lathe, Router, "Ultimate CNC software" |

Centroid Mill, Lathe, Router, "Pro" CNC software

Centroid Mill, Lathe, Router, "Ultimate CNC software" |

| Plasma THC Compatible | Yes | TBA | No | No | TBA |

| Uses Standard G and M codes | Yes | Yes | Yes | Yes | Yes |

| Probing and Digitizing compatible | Yes | Yes | Yes | Yes | Yes |

| Compression and Rigid Tapping Compatible | Yes | Yes | Yes | Yes | Yes |

| Automatic Tool Measurement Compatible | Yes | Yes | Yes | Yes | Yes |

| Spindle Encoder feedback,w/ RPM display | Yes | Yes | Yes | Yes | Yes |

| Lathe Constant Surface Speed | Yes | Yes | Yes | Yes | Yes |

| Lathe Threading | Yes | Yes | Yes | Yes | Yes |

| Compatible with Windows 10/11 | Yes | Yes | Yes | Yes | Yes |

| Centroid Touch Screen Operator Control Panel Compatible | Yes | Yes | Yes | Yes | Yes |

| Centroid Operator Control Panel Hardware Compatible | No | Yes | Yes | Yes | Yes |

| Xkeys & Xbox Controller/Panel Compatible | Yes | Yes | Yes | Yes | Yes |

| Centroid CNC Console Compatible | No | Yes | Yes | Yes | Yes |

| Keyboard Jogging and controls compatible | Yes | Yes | Yes | Yes | Yes |

| Encoder Expansion Board Compatible | No | Yes | Yes | Yes | TBA |

| PLC Expansion Board Compatible | Yes | Yes | Yes | Yes | Yes |

| Analog IN/OUT Expansion Board Compatible | No | Yes | Yes | Yes | Yes |

| Wireless USB MPG Compatible | Yes | Yes | Yes | Yes | Yes |

| CNC Configuration Wizard | Yes | Yes | TBA | TBA | TBA |

| Built in Encoder ports | 1 | 3 | 6 | 6 | 3 |

| Maximum # of Encoder connections | 1 | 9 | 12 | 12 | 3, future encoder exp. planned |

| Maximum # of Analog outputs | 1 | 6 | 17 | 17 | 2, future analog exp. planned |

| Velocity Mode | No, (Step and Direction only) | No, (Step and Direction only) | No, (Closed Loop Torque Mode) | Yes | No |

| Position Mode | No, (Step and Direction only) | No, (Step and Direction only) | No, (Closed Loop Torque Mode) | Yes | Yes, via EtherCAT |

| Real Time Hardware Based Step and Direction Output | Yes | Yes | No | No | No |

| Axis Motor Tuning | Yes, Accell/Decell | Yes, Accell/Decell | Yes, Built in Tuning Scope for PID Tuning | Yes, Built in Tuning Scope for PID Tuning | Yes, Built in Tuning Scope for PID Tuning |

| Motion control off-loaded from CNC PC CPU | Yes | Yes | Yes | Yes | Yes |

| G code Smoothing | Yes | Yes | Yes | Yes | Yes |

| DIY Kits available | Yes | Yes | Yes | Yes | Yes |

| Any axis can be Linear or Rotary Axis | Yes | Yes | Yes | Yes | Yes |

| Rotary Table Compatible | Yes | Yes | Yes | Yes | Yes |

| Build your own compatible CNC PC | Yes | Yes | Yes | Yes | Yes |

| Factory CNCPC with preloaded CNC software available for purchase | Yes | Yes | Yes | Yes | Yes |

| Runs on regular 110 VAC power (USA market 110 VAC, World 220-240 VAC) | Yes | Yes | Yes | Yes | Yes |

| Spindle Motor can run on single phase 220-240 VAC | Yes | Yes | Yes | Yes | Yes |

| Designed and Made in USA | Yes | Yes | Yes | Yes | Yes |

The Centroid CNC control is a hybrid PC based CNC control. Hybrid = The Centroid CNC12 software runs on a Windows 10/11 PC with Ethernet communication to the dedicated Centroid CNC Hardware.

All the critical Machine Tool motion and control is performed by the Centroid hardware on board Motion Processing Unit (MPU) and the Centroid PLC.

This Centroid hybrid architecture combines the best of both worlds using a CNC computer that’s non-proprietary, widely compatible, reliable, affordable, and user serviceable in combination with dedicated CNC hardware while avoiding the drawbacks of either a fully PC-based CNC control or a fully proprietary architecture at the same time.

With Centroid, the Windows PC is being used for the user interface, while all the essential high speed machine tool motion and functions are being handled by the Centroid dedicated on-board Motion Control processor and the on-board Centroid Programmable Logic Controller.

Pros: This hybrid CNC architecture approach combines the benefits of a PC's versatility, price, availability, compatibility, user friendly right to repair/replace/update with the stability and precision of dedicated CNC hardware, providing the best of both worlds in a CNC control while avoiding the pitfalls and expenses of either.

All High-speed, critical functions are handled by Centroid dedicated hardware for high performance and reliability. Any issues with the PC, such as CPU problems or Windows/HD glitches, do not impact the CNC machine's operation or performance.

Seamless integration of CAD/CAM software and networks, with no compatibility hurdles.

Low cost using off-the-shelf PC hardware for easy upgrades, maintenance and replacement. Replace and upgrade the CNC PC without having to upgrade the Centroid CNC Hardware!

User-friendly interfaces (e.g., touchscreens) and broad compatibility.

Balances PC ease-of-use with embedded real-time precision. Highly flexible with open architecture API for custom software and networking.

Scalable for multi-axis control without full custom hardware; unified vendor support simplifies setup and maintenance.

Cost-efficient and user-friendly operation with easy learning curves saving time and money.

This arrangement is the best of both worlds, a PC for a non-proprietary, wide compatibility, reliable, affordable, serviceable CNC computer without having the problems of a fully PC based CNC control as any issues related to the PC CPU usage or a momentary Windows glitch will not affect the CNC machine tool operation as both the CNC PLC and Motion control is performed on directly on our hardware by our integrated firmware (which auto updates with each new Centroid CNC software release, so there are no drivers to mess with or other complicated procedures).