Acorn and AcornSix Laser CNC Control

This is a legacy page, to view up-to-date information and pricing please visit the Acorn and AcornSix Laser Page on ShopCentroidCNC.com

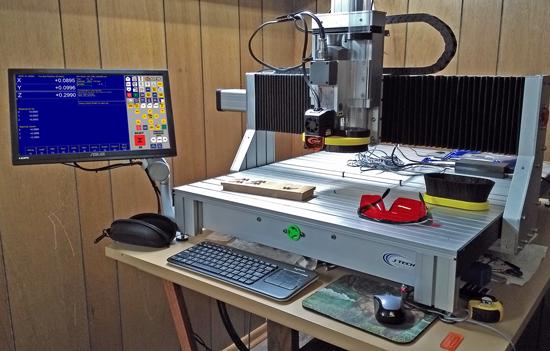

Acorn and AcornSix CNC control Laser Engraving CNC controller kits are both a CNC Hardware and CNC Software DIY system designed to work together for easy CNC setup and operation with minimal fuss. Works with a wide varitey of PWM controlled Lasers. Centroid Laser CNC controller kits are both a CNC Hardware and CNC Software DIY system designed to work together for easy CNC setup and operation with minimal fuss. Works with a wide variety of PWM controlled Lasers. The Centroid CNC Laser cutting and engraving system has useful CNC Laser features such as Laser Power Velocity Modulation where the Laser Power is adjusted automatically based on actual machine velocity.

Easy Laser setup is in the Acorn and AcornSix setup Wizard click here more info on seutp and configuration.

see Centroid Laser Hookup Schematic examples are here, type in "laser" in the search field.

Acorn and AcornSix Laser Video Gallery

The Centroid Acorn and AcornSix support a wide variety of PWM controlled Lasers with easy hookup to the CNC controller and simple configuration setup by using the Setup Wizard

LaserGRBL Header and Footer info for Centroid Acorn Laser compatible G code.

HEADER

------

G21 ; select metric units

G90 ; absolute positioning

G0 X0 Y0 ; rapid to X0Y0

Z0 ; Move to Z zero

G37 ON ; Auto Laser power Velocity Modulation ON

M3S0 ; Laser power off

M37 ; Laser on

MULTIPLE PASSES

--------------

;(Uncomment if you want to sink Z axis)

;G91 (use relative coordinates)

;G0 Z-1 (sinks the Z axis, 1mm)

;G90 (use absolute coordinates)

FOOTER

------

S0

G90 ; Absolute positioning

M38 ; Laser cool down time

;END

Sample G code

G21 ; select metric units

G90 ; absolute positioning

G0 X0 Y0 ; rapid to X0Y0

Z0 ; Move to Z zero

G37 ON ; PWM Laser Power Velocity Modulation ON

M3S0 ; Laser power off

M37 ; Laser on

G0 X-74 Y-36.5 F2000

M3 S0

G1 X-73.833 S207

X-73.667 S203

X-73.333 S201

X-73.167 S203

X-73 S209

X-72.667 S213

X-72.5 S211

X-72.333 S215

X-72.167 S217

X-71.833 S215

X-71.667 S213

X-71.5 S205

X-71.333 S211

X-71.167 S207

X-71 S200

X-70.667 S203

X-70.5 S196

X-70.333 S190

X-70.167 S192

X-70 S194

X-69.333 S200

X-69.167 S198

X-69 S196

X-68.833 S198

X-68.667 S203

X-68.5 S207

X-68.333 S205

_________________________________________________

LightBurn Setup informaiton and work flow is here.

https://centroidcncforum.com/viewtopic.php?p=95845#p95845

Centroid Acorn CNC controller reviews

"Looking to order boards and other parts from you this week. I've got to admit - SO NICE having a board and software made by the same company. No plug ins from other places and the headaches. Literally followed the video and the motors were turning by the time it was done.

- Revy

"After dealing with Mach 3 and LinuxCNC for years, I must say Centroid is Light years ahead. Up and running bench test in a matter of minutes instead of days as with those other products. There is much to learn about Centroid but I am confident it is a very solid product. I can't find the words to properly describe the difference."

- Makeron

"My son came to me and said that the students in his high school woodworking class could not finish their projects due to their CNC router is broken. Well I couldn't let this be and in less than an hour, I installed a acorn on their router and all the students were able to finish their projects. I donated the board to the school so they could continue to use the router and many students will be able to familiarize themselves and use the Centroid control. Thank you Centroid for making such an awesome easy to use and install product. Keep up the good work!"

- Extreme industrial

I have to say a big THANK YOU to Centroid for providing the best value in DIY CNC on the market today. I just completed the upgrade of my CNC router table to Acorn and couldn't be happier! Followed the schematics for the GeckoDrive 203V (only thing I kept from my old controller) and everything just worked without any issues. Watched a lot of video's that provided almost everything I needed to get my machine working. I saved so much money over upgrading to Mach4, Smooth Stepper and PMDX boards that I had planned for my initial upgrade that I bought a touch screen monitor, wireless pendant and upgraded to Mill Pro. The pendant is just amazing to use. I feel like I have a professions system now! Not sure how you can sell the entire acorn kit for the price you do, but thank you for providing this to the DIY community.

- cnc_jim

Yesterday, I received a model 4 Acorn and an extra relay board for my model 3 Acorn that I bought almost a year ago. Opening that package reminded me of the care and concern that Centroid has for its customers. The power supply was pre-wired for the Acorn. The instruction sheet is comprehensive. The backside of the instruction sheet that shows a connection schematic that should make initial connections fool-proof. I just noticed that even those schematics are printed in color. (My eyes have serious problems.) The new schematics that Keith notified us of have fixed all of the connection problems that I've experienced with ClearPath servos, Gecko G203 drives, and Leadshine (clone) drives. Those problems were not Centroid's fault. (The older schematics followed wiring diagrams from other manufacturers that were somewhat lacking. I've read Teknic's manual carefully about the fault signal. The older schematics followed the Teknic manual. Keith and Gary solved that problem months ago, but because I had a work-around, I didn't carefully read the revised schematic that Centroid published months ago.) I was able to work around those problems; but the new schematics make those work-arounds obsolete. It amazes me that Centroid is willing to spend money on so many do-it-yourself motors, drivers, spindles, VFDs and other non-Centroid products, test those products, draw up schematics to use those products and still sell the Acorn for $329 with the amazing Centroid software.

Next, the forum along with YouTube videos are great. Keith, Marty, Gary and Franco not only show how to use the Acorn, but teach general principles about CNC machining. Late last night when I couldn't sleep, I watched a video where Keith showed how to use a vertical mill. The video contained everything that anyone would need to see how to use Centroid products to make their equipment work. Clicking on "Acorn User Videos" from the Acorn page shows a list of videos that show how to use the Acorn. Going on YouTube and searching "Marty CNC" brings up Marty's channel with a comprehensive list of how-to videos. Searching "Gary Campbell CNC" brings up Gary's channel and his expertly produced videos. (Gary and I go back decades to my Shopbot days when I constantly used his advice to solve my problems.) Clicking on "Centroid CNCKeith" brings up Keith's videos. His knowledge and easy-going style should make anyone comfortable in trying an Acorn. One of his videos was with "MecTechMike". Mike's mill and lathe conversions should impress everyone. He surely impressed me and gave me ideas that will take at least a year to try. There are many, many others who have taken the time to post videos showing how they use the Acorn and other Centroid products.

The forum is invaluable. Questions are answered expertly (in most cases). Since I tend to be disruptive in some of my posts (unintentionally - I like to think outside the box and try things that might seem to be controversial), I expected harsh feedback or even censoring, but I've been treated with respect and courtesy. More, importantly, by reading what others are doing, I get ideas that would take a life-time to implement.

Thanks Centroid and thanks to all of you in the Acorn community for your help.